Focuses on the pain points of production management and supports enterprises transforming to intelligent manufacturing with cloud-native environment, reducing operating costs, and developing core competitive advantages.

Lack of quality control measures in the production process affects product stability and customer satisfaction. Enterprises have not established a complete quality traceability system and lack supporting data to demonstrate quality improvement.

Due to inaccurate resource planning, delays in material supply, unplanned downtime, and more, it can result in the suspension of production or a slow production cycle, affecting the order fulfilment.

Lacking information about the production process and performance metrics results in not being able to obtain the real-time production status. Continuous checks and follow-ups lower the communication and collaborative efficiency.

Customised production, high demand uncertainty, frequent changes in plans, lack of flexibility in planning, poor scheduling, and unable to quickly transform external demand into internal production and procurement requirements means that production cannot be carried out in an orderly manner.

Data empower management and lead for continuous improvement.

Implementing Sales & Operations Planning (S & OP) Process

Connect the business to cloud-native environment and manufacturing

Diversify, Customize, short lead time, and small batch production

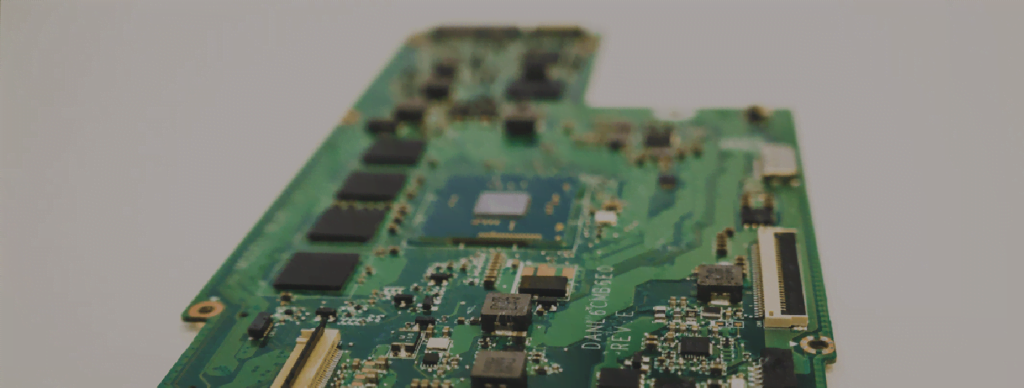

The mature architecture of the industrial Internet platform helps manufacturing enterprises improve their digital capabilities, optimizes costs and increases efficiency to develop sustainable competitive advantages.

Manufacturing cloud forms the linkage of different hierarchy levels including C-level, management level, execution level through the industrial network, achieving two-way communication and real-time data sharing. The IOT platform in the bottom with high connectivity to the production devices, enabling real-time collect production and material data;

The smart manufacturing platform in the middle allows management in every part of production processes; The cloud platform at the top enables data sharing and real-time monitoring, allowing improvements in speed to market.

Kingdee’s intelligent manufacturing solution, from manufacturing processes, supply chain management, and Omni-channel marketing, seamlessly integrates business processes, enables speedy and timely production planning, adheres to sales needs, and refines an enterprise’s management costs.

Since Kingdee already has a set of comprehensive system, which can customise according to customer’s needs. Therefore, when we set up a new company or expand business, the comprehensive system is tremendously helpful to the business growth. As the old saying goes: ‘Good tools are prerequisite successful execution of a job.’ I think Kingdee can achieve this effect.

“With the help of Kingdee Cloud, we are able to achieve efficient operation of offline supply chains, distribution centers, and online malls and communities, as well as make use of a large amount of data. Bliss Cake has also achieved zero-inventory production. We are able to deliver products to customers within two hours and offer products based on their preferences. By teaming up with Kingdee Cloud, we offer not only cakes but also happiness.”

From the manual work of running the system to a brand new model to change our habit of application, from democratic form to centralization, and from centralization back to democratic mode for linking online to K/3 system.

In 2015, Casablanca teamed up with Kingdee to improve its information management system. Based on Casablanca’s operating model and the management’s IT application requirements, a corporate financial system has been established to facilitate its management and business operations. Built based on the business system of each unit, the system generates data for each unit and each store via Kingdee Cloud Galaxy. It enables Casablanca to conduct big data analysis via the BI system, carry out Amoeba-style profit assessment on each unit, automatically collect data with a high degree of data transparency and obtain analysis reports for decision-making purposes in an efficient manner.

If you have any questions, please call us at (852) 2157 9390. Our consultant will give you the best solutions for Digital Transformation.

Kingdee’s Product

©2023 Kingdee International Software Group (HK) Ltd. All rights reserved.