King Dee Constellation EBC Platform – Manufacturing Cloud

Integrate digital technology with lean production, build a digital factory, promote enterprise integration into the industrial internet,

achieve interconnectivity across all elements, industries, and value chains, and reshape the enterprise value chain.

enterprise value chain

Industry-leading Collaborative Manufacturing Platform

Kingdee Constellation – Manufacturing Cloud integrates digital technology with lean production, supporting manufacturing enterprises in responding to uncertainties developing resilience in this everchanging world. Our platform focuses on digital applications and smart manufacturing through vertical, end-to-end, and horizontal integration. It establishes a digital production mode that emphasizes interconnection, collaboration, and optimized productivity. The data-driven management model enables enterprises to respond with velocity and flexibility, which essentially will convert to steady and quality business growth.

Online Collaboration

By connecting the vertical market in the industrial chain, we enable a seamless end-to-end process from design, planning, procurement, manufacturing, delivery, and operation. This results in optimal visibility, efficiency, and cost reduction throughout the production process.

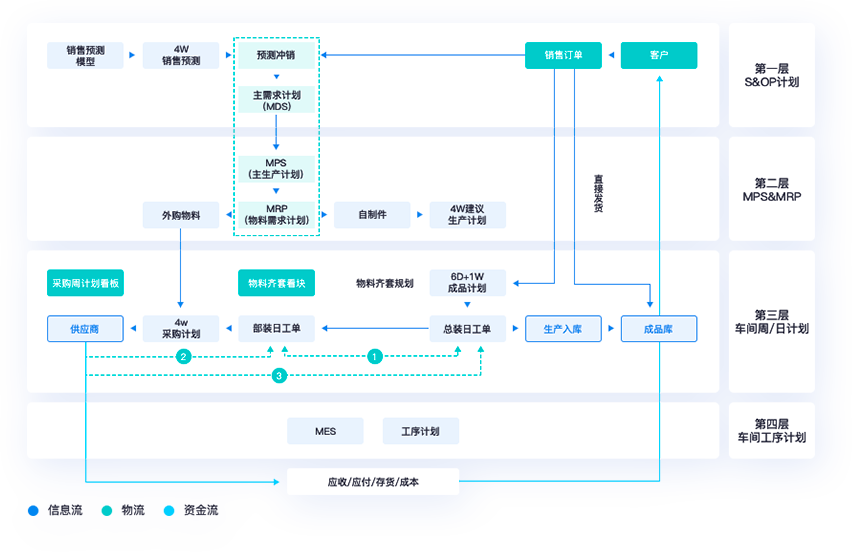

Flexible Planning System

Our supply chain planning solution provides a comprehensive and adaptable approach to meet the needs of businesses across multiple levels and organizations. With a range of powerful capabilities integrated into the system, we empower businesses to enhance their supply chain efficiency through a multi-perspective approach. The highly configurable solution with flexible planning schemes, processes, and algorithms can be customized to various scenarios and growth stages of the business.

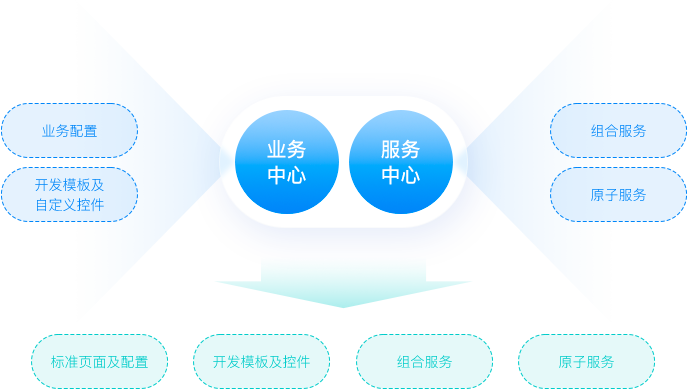

Modular Business Support

We have built a manufacturing business middleware from identifying the fundamental attributes and nature of the manufacturing industry, supporting the four core areas: engines, manufacturing fundamentals, mold casting, and business operation. Re-use, resource sharing, innovation, and modular capacity are enabled at once.

Efficient Manufacturing Actualization

We support the flexible combination of various manufacturing modes by integrating a lean production structure, on-site production optimization approach, pull production, efficient logistics, smart Andon system, online quality inspection, equipment maintenance and digital operation.

Multi-tasking Project Execution

Our planning-driven approach streamlines the design, procurement, and production process by supporting multi-task concurrency and one-stop change management. Our platform allows for high-frequency changes while facilitating the design and verification processes simultaneously, supporting enterprises in shortening delivery time, lowering operating costs, and improving overall efficiency.

An Open Unifying Platform

Our comprehensive solution covers every aspect of your manufacturing business, from planning and manufacturing execution to equipment management, MES, safety, health and environmental protection, WMS, QA, QC, and manufacturing operations. Our integrated applications are designed to improve efficiency and streamline your entire manufacturing process.

Smart Operational Decisions

Leveraging real-time data supervision, our solution transforms the operation mode from process-driven to a data-driven approach, delivering visibility and transparency across business operations. This ensures optimized productivity and execution of business strategies.

Safe and Green Manufacturing

With the continuously growing concern around energy conservation, emission reduction and environmental governance, resources and production environment are strictly regulated. Kingdee Constellation Cloud provides EHS management solution, supporting enterprises in achieving their strategic initiatives in green and sustainable production.

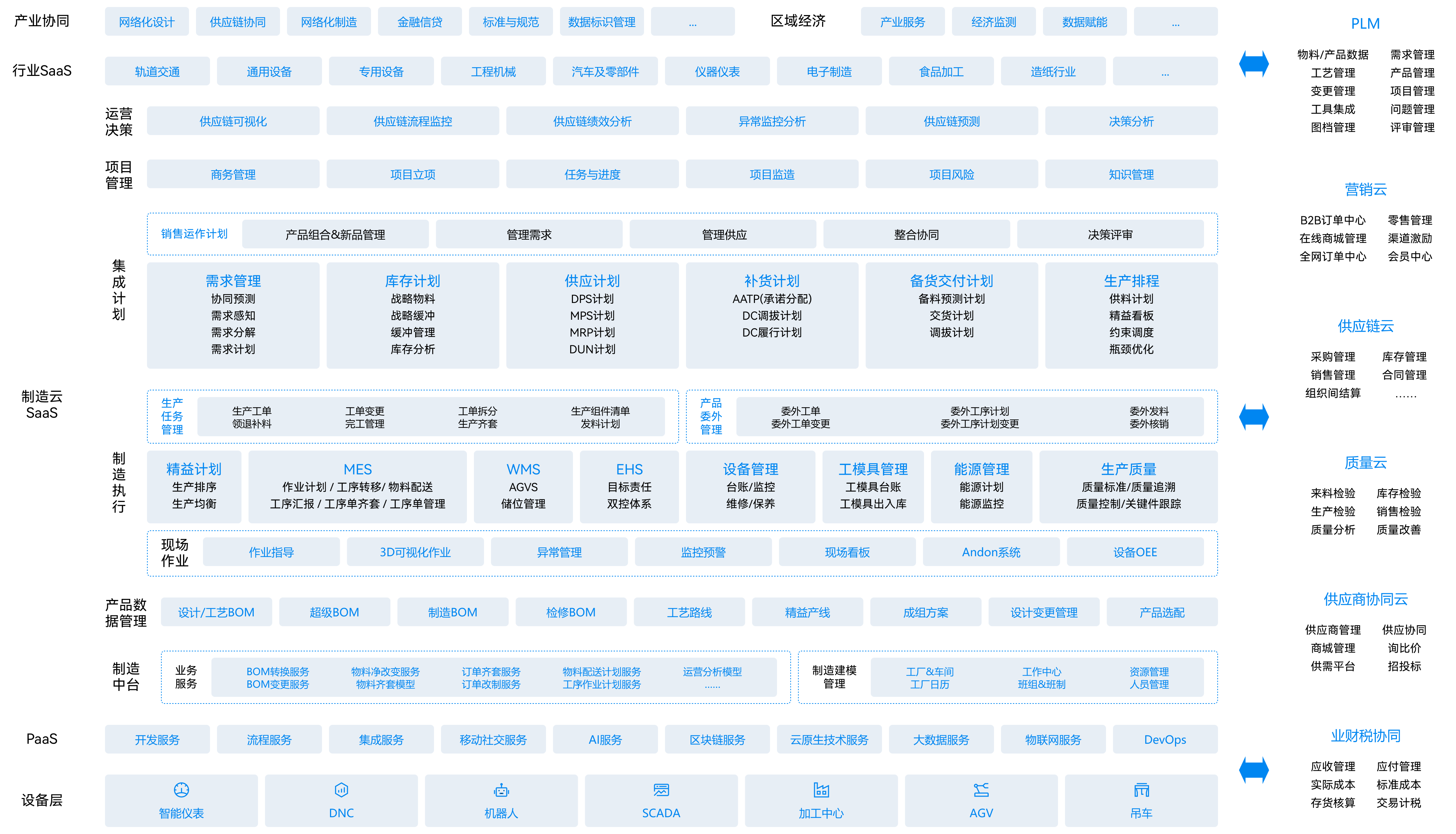

Kingdee Constellation – Manufacturing Cloud Structure

Support enterprises in reconstructing digital power with online collaboration, manufacturing middleware, and operational management

Flexible Product Data Management

Product data management supports sustainable R&D, executable manufacturing, clear planning, pre-emptive procurement, and isolated data.

- Manage your BOM from multiple business perspectives with multi-formats

- Drive business collaboration with one-stop change management

- Match modular design application requirements with customized material configuration

- Meet complex and flexible production process requirements by supporting numerous production processes

- Deepen collaboration between design and manufacturing

Flexible Planning System

We create an assembly-ready flexible plan based on the “supply-demand equilibrium model.” Our visible real-time calculation process and easy-to-use guided configuration allows customization that provides large-scale manufacturing enterprises with adaptability for business planning, and agility for swift response to the market.

- Our planning system is designed to enhance supply chain efficiency through a multi-perspective, multi-level, and multi-organizational approach that integrates multiple parties.

- Multi-dimensional sales projection

- Flexible demand and supply projection model – our multi-dimensional approach utilizes factors including such as regions, sales channels, customers, product lines, SKU and other historical data.

- Strengthen overall planning coordination with MRP operation under a multi-organizational company group framework.

- Drive your business with strategic planning to meet order requirements and optimize inventory levels.

Efficient Manufacturing Actualization

Our manufacturing software supports MTS, ATO, MTO, and ETO modes, and is also compatible with mixed manufacturing across multiple industries. Highly flexible, it can manages various work processes such as order splitting and merging, transferrals, task designation, and rework, ensuring actualization.

- Flexible and diverse production modes, using a mix of various manufacturing modes

- Simulate complete sets of upcoming products based on inventory or in-transit materials

- Global demand planning for materials under multi-company, multi-factory production modes

- Unique backflush platform supporting precise material consumption allocation for bulk retrieval after warehousing

- Enhanced BOM management to include outsourced materials, manually added components, and repair of primary products

Multi-tasking Project Execution

Our user-centric manufacturing solution covers the full project lifecycle, deeply integrating project management modes. The plan-driven approach enables efficient simultaneous processing, reducing waiting time, wasted resources across all business areas, and operational costs. The intended outcome is to enhance value for customers in all aspects, including products, costs and quality.

- ” Simultaneous project operation, support, and quality management for streamlined production, supply, and sales processes”

- Collaborative design, procurement, production, and quality management for significant lead time reduction

- Parallel timeline for design, verification, and production with high adaptability to frequent changes

- Integration of project estimation, budgeting, accounting, and cost management for comprehensive project control

- Real-time monitoring of budget, cost, profit, and risk for informed decision-making

Smart Operational Decisions

We offer a data-driven solution that provides continuous online monitoring and diagnosis for business processes across the entire enterprise data chain. By analyzing various business scenarios, a closed-loop mechanism is established for end-to-end event response, processing, and closure. The industry-specific model helps improve overall enterprise performance.

- Real-time monitoring on work processes with clear performance indicators

- Collaborative features across regions, factories, businesses, and departments

- Process-driven and data-driven operational model

- Assured optimized productivity with transparent operational model

Green manufacturing for safety and sustainability

Kingdee Constellation Cloud Safety Control Solution creates a PDCA cycle of safety production goals, systemized processes, and measured results, continuously improving and enhancing production safety and efficiency. Visibility, accident prevention and process control are achieved in one gal, making manufacturing green and sustainable.

- Deeply integrated digitization for safe production and environmental management

- Monitoring primary hazards

- Comprehensive safety risk management

- Efficient production process management

- Green operation center

Smart IoT

By integrating cutting-edge technologies such as IoT, edge computing, cloud computing, big data visualization, and AI algorithms, we have designed a comprehensive one-stop solution for full product management throughout the manufacturing lifecycle, consisted of Industrial Gateway + IoT Platform + SaaS applications.

- Smart services: smart network, data acquisition, remote maintenance, smart control panel, and data analysis

- Bridging the gap between OT and IT with the power of industrial data

- Supporting production, equipment, energy, safety, environmental, and product management

- Adaptable to various vertical industries, including smart factories, smart city or district initiatives, smart agriculture, and smart equipment

Middleware services for modular manufacturing

Our solution provides a high-productivity PaaS platform with powerful computing capabilities and a plug-and-play computing framework. It supports end-to-end integration from planning, production to sales, helping manufacturing enterprises achieve a seamless production line.

- Personalized expandable business algorithms – quick adoption and system configuration

- Personalized billing documentation engine – on-demand assembly with 0 code required

- Four core areas to kickstart a new business: engines, manufacturing fundamentals, mold casting, and business operation

- Complete end-to-end integration capabilities with internal and external connection standard definitions, adaptable to existing corporate infrastructure

Unleash the power of lean manufacturing with our digital platform

Achieving unified planning, control, and collaboration across multiple factories and warehouses with a combined planning approach

With the application of Kingdee Constellation Cloud, Yunnan Tobacco has been able to connect 20,000+ employees and 10,000+ suppliers, achieving real-time planning and production-sales collaboration in the combined planning mode with multiple factories and warehouses.

FAQ

Yes. Kingdee Constellation – Manufacturing Cloud is designed to support the construction of a middle-end platform for large-scale manufacturing enterprises. It is also the preferred product for large enterprises to build cross-factory and cross-enterprise manufacturing middle-end platforms.

The platform offers various business services, including basic manufacturing data, factory models, demand and supply models and algorithm engines. It also caters to product data and engineering revisions, strategic planning, suppliers’ collaboration, production support, equipment management, and quality assurance. The middle-end with supply chain and financial support centralizes the management force to effectively monitor and maintain the manufacturing process, enabling a management model with high transparency and digital capacity.

Yes, Kingdee Constellation – Manufacturing Cloud highly focuses on digital operation of the smart factory model. Designed based on edge and business data, the solution is supported by the manufacturing middle-end platform, activating potential collaboration among the horizontal markets. As a result, enterprises can develop the centralized control panel that serves as the corporate brains and a platform for manufacturing collaboration. The successful stories of Yunnan Tobacco and CRRC ZELC have demonstrated the game-changing benefits Kingdee Constellation – Manufacturing Cloud offers.

Kingdee Constellation – Manufacturing Cloud is a business planning model that combines supply-demand assessment and strategic planning. It supports parallel execution and integration of numerous manufacturing strategies, including ETO, MTO, ATO, and MTS. The calculation, process design, and algorithm are all configurable and highly customized. The MRP mechanism has totally transformed into a highly flexible, agile and adaptable model that caters to various scenarios and developmental stages of an enterprise.

The industrial chain of large and complex manufacturing enterprises is often complicated. Kingdee Constellation – Manufacturing Cloud has built a collaborative platform for suppliers and enterprises in the full manufacturing lifecycle, covering product data, order placements, production planning, and quality assurance. Through the highly collaborative and interactive interface, enterprises and suppliers are empowered to co-manage all aspects throughout any project on a centralized platform, ensuring effective productivity management.